企業情報

Company information

Quality and Safety Policy

We place Azumino at the core of our brand, with a commitment to becoming a globally essential company, starting from Azumino itself. Our approach involves strict adherence to legal regulations, a vigilant emphasis on product hygiene and quality management, and the continuous enhancement of our corporate competencies. Our primary goal is to offer products that prioritize safety, security, and customer satisfaction while effectively communicating essential food safety information to our stakeholders. Furthermore, we consistently strive for improvements in the effectiveness of our management systems in alignment with ISO and FSSC22000 standards.

2023 March 21

Marui Corporation

Ren Iguchi

President and CEO

Our Commitment to Quality

Wasabi's unique flavor, which swiftly travels from your mouth to your nose, embodies its true essence.

That's why we're dedicated to keeping it fresh, which in turn enhances its quality.

Our company, located in the heart of Azumino, Nagano, Japan's top wasabi-producing region, takes full advantage of its surroundings.

The wasabi we harvest is quickly processed with natural groundwater and frozen the same day.

In our factory, we rely on stable groundwater from the Northern Alps, ensuring consistent water temperatures throughout the year, from processing to raw material. Notably, we do not rely on tap water during our manufacturing process.

Obtained FSSC22000 Certification.

We have obtained FSSC22000 certification. We will continue to promote and implement continuous improvements in our food safety management system to enhance food safety.

Design, Development, and Manufacture of Spices (Wasabi, Ginger, Mustard, Yuzu) and Processed Foods Containing Spices (Wasabi, Ginger, Mustard, Yuzu).

At the entrance of our factory, we have installed an air shower. This system, equipped with air filters, operates at a higher pressure than the outside air, effectively blocking external air. Furthermore, we maintain rigorous temperature control within the factory.

Ensuring the 'Safety and Security' of Our Products

We manage the entire process from raw material receipt to shipment,

ensuring traceability.

We oversee the entire production cycle, from the moment we receive the raw materials until the products are ready for shipment, maintaining a robust traceability system.

When raw materials arrive, they undergo batch-specific inspections and are then carefully stored, preserving traceability.

Additionally, comprehensive records of inspections performed at various stages of production are meticulously archived to ensure traceability.

Furthermore, we place a strong emphasis on preserving cultivation records for our contracted farmers, which are efficiently managed in a centralized manner.

Our commitment to delivering safe, top-quality products compels us to continually enhance our quality management practices.

In the cleaning phase, we employ running water to meticulously eliminate any foreign substances that might have entered the raw materials.

To bolster 'safety and security,' we incorporate metal detectors during the final inspection at each stage of production.

Additionally, regular training sessions are conducted as part of our ongoing efforts to raise awareness among our staff.

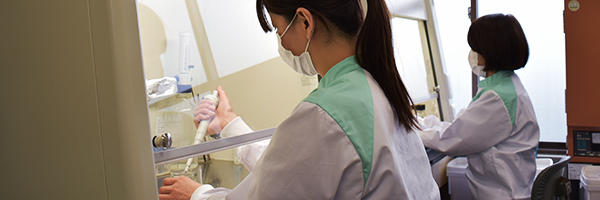

When raw materials are received, we take batch-specific samples, which are subjected to rigorous examination in our laboratory.

These evaluations encompass not only the assessment of raw material quality, including microorganisms and foreign matter but also the scrutiny of spiciness and aroma.

Any raw materials failing to meet the prescribed standards are promptly identified and removed at this stage in the process.